How BBQ Gas Bottles – Propane Tanks – Are Made

The manufacturing of BBQ gas bottles – propane tanks – requires excellent quality control to assure long life and safe use.

The manufacturing of BBQ gas bottles – propane tanks – requires excellent quality control to assure long life and safe use.

Most users expect a minimum of 20 years of use, so premium materials and quality manufacturing are a must.

But how are they made?

How LPG Cylinders are Made? How Propane Tanks Are Made?

An LPG cylinder or propane tank, is most commonly made of welded steel.

Two half cylinder shapes are welded together, with foot and neck rings added, to form a single steel cylinder.

In recent years, there has also been an influx of composite cylinders.

Composites use the combination of an inner liner of polyethylene (HDPE), wrapped glass fibers and resin, and a polyethylene (HDPE) outer casing.

What is an LPG cylinder made of?

There are three common materials used to make LPG cylinders.

Steel is by far the most common material, as it is the easiest to fabricate and it is a low cost material.

Steel is by far the most common material, as it is the easiest to fabricate and it is a low cost material.

Some cylinders are made of aluminium.

This is quite common for forklift cylinders, relating to safe lifting.

The use of aluminium keeps the weight down to allow for more gas whilst still staying within the safety weight limits.

The most recent innovation is the composite cylinder.

These are typically fiberglass with a high impact plastic outer shell.

Some have an inner lining of HDPE whilst other have a thin steel liner.

Starting with the Cylinder Body

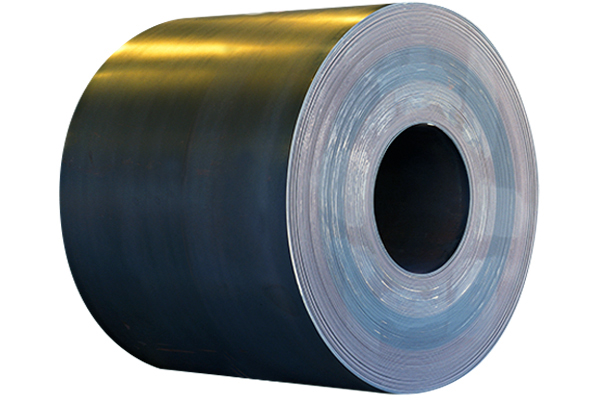

The process starts with a coil of sheet steel.

The process starts with a coil of sheet steel.

The sheet is fed through a strong punch press, creating circular blanks of about 48cm (19 inches) in diameter (image below).

The circular blanks then go through a powerful hydraulic press, as shown below, which draws the steel disc into the shape of a half of a cylinder.

An automated trimmer gives it a clean edge so the two halves can be welded together evenly, without any gaps.

Cylinder Add-Ons

A hole is punched into the top of the cylinder and a threaded valve flange is inserted, as shown.

A hole is punched into the top of the cylinder and a threaded valve flange is inserted, as shown.

An automated welding station, shown in the following image, fuses the flange to the top of the tank.

This provides a secure sealed opening for screwing in the tank valve.

This provides a secure sealed opening for screwing in the tank valve.

Steel strips are punched and formed into the circular foot rings.

The foot ring (shown) is welded to the bottom of the tank with another automated welding machine.

The foot ring (shown) is welded to the bottom of the tank with another automated welding machine.

In a similar process, the neck ring is punched and formed from another strip of steel and welded to the top half of the tank.

The difference is the secondary bending that is done to form the gas bottle handle.

About the Valve

The main valve on a BBQ tank is made out of brass.

The main valve on a BBQ tank is made out of brass.

Why brass?

Brass is considered to be “non-sparking”, so there is less chance of any accidental ignition.

The valve also has an integral Pressure Relief Valve (PRV).

The PRV is the single most critical safety feature on an LPG cylinder.

It is incorporated within the main valve and appears as the protrusion opposite the main connection.

Pressure relief valves are designed to relieve excess pressure that might result from overfilling or exposure to excessive heat or fire.

The function of a PRV is to keep a cylinder from rupturing in the unlikely event of excessive pressure build-up.

The pressure relief valves are held in the closed position by the force of a powerful spring inside.

As long as the pressure is less than that of the spring, the valve will remain closed.

Stamped On Information

The neck ring contains a lot of important information that is stamped into the steel.

This information typically includes:

• Cylinder manufacturer name

• Country of manufacture

• Date of manufacture, which is important for the tank re-testing date reference

• Test station identification

• Tare weight – empty weight of the cylinder

• Water capacity, which is indicative of volumetric capacity

A hydraulic stamp is used to embed this information into the steel of the neck ring.

Space also remains on the neck ring for additional date stamps, required when the cylinder is retested in the future.

Final Assembly

The two tank halves come together and are welded in a special rotary welding station (shown below).

The two tank halves come together and are welded in a special rotary welding station (shown below).

Entire tank is then heat tempered, in a furnace (as shown below), to provide for the correct hardness required for the expansion and contraction that occurs during pressurisation.

Tanks are painted on an automated electrostatic paint line with electrostatically charged powdered paint, as seen in this image:

Tanks are painted on an automated electrostatic paint line with electrostatically charged powdered paint, as seen in this image:

This process helps assure full and even paint coverage.

The last assembly step is the valve insertion (below) and tightening.

The last assembly step is the valve insertion (below) and tightening.

Testing

There are a number of tests performed to assure a quality product.

Testing is done on the weld seams to assure that they are as strong as the adjacent steel.

A water pressurisation test is done to test for expansion. This assures that the heat tempering was properly done.

Prior to valve insertion, the tank undergoes an internal inspection, using a small video camera, to look for contamination or corrosion inside the tank.

Prior to valve insertion, the tank undergoes an internal inspection, using a small video camera, to look for contamination or corrosion inside the tank.

The final test involves the air pressurisation of the tanks, whilst they are submerged (shown), to test for leaks.

Final Thoughts

Most people don’t realise how much goes into making a BBQ gas bottle.

Quality is paramount to ensure long life and safety.

- Elgas to the Rescue with Helicopter LPG Delivery - November 14, 2024

- Outdoor Heaters: Outdoor Gas Heaters – Gas Patio Heater Guide - September 22, 2024

- LPG Meaning – LPG Means: What Does LPG Stand For - August 31, 2024

Steve Reynolds

Technical Consultant

Steve Reynolds is a leading expert in the LPG industry with over 22 years of experience. As part of the national management team at ELGAS, Steve ensures the safe and efficient storage, handling, and transportation of LPG. He serves as the lead investigator for incidents and collaborates with authorities on industry developments.

Steve is a technical advisor to Standards Australia and Gas Energy Australia (GEA), and an active member of the World LPG Association (WLPGA), contributing to global standards and technical reviews. He holds a BSc. (Hons) in Industrial Chemistry from UNSW and has held senior safety and technical roles at ELGAS, making him a trusted authority in LPG safety and standards.