9kg Gas Bottle Instead of a 45kg Gas Bottle – Can I Connect a 9kg Gas Bottle to My House

![]() Can you use an 9kg gas bottle instead of a 45kg gas bottle? People want to connect a 9kg gas bottle to their house in case they run out of gas and are waiting for a 45kg gas bottle delivery.

Can you use an 9kg gas bottle instead of a 45kg gas bottle? People want to connect a 9kg gas bottle to their house in case they run out of gas and are waiting for a 45kg gas bottle delivery.

This blog discusses the potential problems you may encounter by downsizing your gas bottle.

The Answer is “It Depends”

There are several factors to consider when you are thinking about switching the size of gas bottle that powers yours LPG gas appliances:

What is the gas load of the appliances you are trying to power?

What is the gas load of the appliances you are trying to power?- How full is the gas bottle?

- What is the ambient temperature?

- Is the gas in the bottle propane, butane, or a mixture of the two?

- Is the installation safe for an 9kg gas bottle?

All these factors affect the vaporisation rate or safety of using a smaller bottle instead of a larger one.

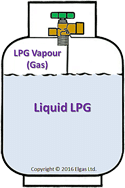

Vaporisation is how fast the liquid LPG fuel can turn into a gas inside the cylinder.

LPG Vaporisation

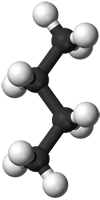

The LPG (propane and/or butane) turns from liquid to gas when it boils in vaporisation. For LPG, its boiling temperature is -42°C.

To boil, the liquid LPG draws heat from the steel walls of the gas bottle, which, in turn, gets heat from the ambient air, as shown in the image.

The LPG liquid boils and turns into gas vapour when this happens, as a result of you releasing some pressure in the gas bottle by turning on your gas appliance.

As with water, the more heat applied, the more rapidly it boils and vaporises.

Obviously, a 9kg gas bottle has a much smaller wall area than a 45kg gas bottle, so less heat absorption and less gas output.

Vaporisation Must Match Consumption

The amount of gas drawn from the gas bottle to fuel your gas appliances must be matched by the vaporisation rate.

Appliances are rated by their gas consumption rate, in either MJ/hr or BTU/hr.

Gas fitters use vaporisation tables for proper cylinder selection.

These match the required vaporisation rates to the corresponding vessel size.

Vaporisation tables show the maximum continuous vaporisation rates in MJ/hr or BTU/hr.

This is calculated at different ambient temperatures for each available vessel size.

Gas Bottle Size Matters

If it’s not clear by now, gas bottle sizes make a difference.

If it’s not clear by now, gas bottle sizes make a difference.

Switching to a smaller vessel results in a lower rate of vaporisation because there is less surface area and volume of liquid fuel to boil.

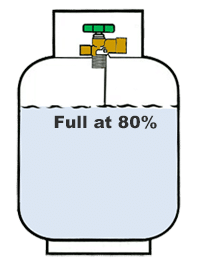

To better understand this, note that heat is absorbed through the vessel shell and into the liquid.

This area of liquid-to-steel contact is known as the “wetted area”.

The larger or fuller the tank, the larger the wetted area since more parts of the cylinder body are in contact with the liquid fuel.

This means more gas can be vaporised at a given temperature, resulting in a higher vaporisation rate.

Show Me My Price

Lower Fill Equals Less Vaporisation

Considering the concept of “wetted area,” the maximum rate of vaporisation drops as the bottle’s fill level drops.

Considering the concept of “wetted area,” the maximum rate of vaporisation drops as the bottle’s fill level drops.

If there is less LPG in the vessel, there is less contact area between the liquid LPG and the steel.

This reduces the available heat for vaporisation.

When the LPG reaches a very low level until it’s empty, you must refill your cylinder.

For example, if the bottle is half empty, the vaporisation rate will be roughly halved. If the consumption rate of the attached appliances is low, this makes little to no difference.

However, if the consumption rate is high, the vaporisation rate may not keep pace with the consumption. It may work fine when full, but then there are problems as the level decreases.

Depending on the appliance, this starvation may cause the appliance to function poorly or not at all.

Temperature Also Affects Vaporisation

When the ambient temperature drops, the steel of the cylinder absorbs and transmits less heat to the regulating valve.

As a result, less heat is transferred to the liquid LPG inside the cylinder. This decrease in heat leads to a lower rate of vaporisation.

If vaporisation and consumption were already closely matched, this heat reduction could cause problems, as the vaporization rate may no longer keep pace with consumption.

Propane vs. Butane

Propane and butane have different boiling points — the temperature at which it goes from liquid to gas (vapour). Propane boils at -42°C, whereas butane boils at -0.4°C.

Propane and butane have different boiling points — the temperature at which it goes from liquid to gas (vapour). Propane boils at -42°C, whereas butane boils at -0.4°C.

This means you have a huge problem if you try to use pure butane when the temperature drops below freezing.

Hence, it may be possible to use propane instead of butane, but not vice versa.

No Boiling = No Vapourisation = No Gas

Pure butane may be problematic for your heater and cooking appliances when ambient temperature drops, especially in winter.

Pure butane may be problematic for your heater and cooking appliances when ambient temperature drops, especially in winter.

Some households in these areas pay for LPG gas cylinders with propane-butane mixtures to address the problem.

This can work well when temperatures are both below and above freezing.

However, if there is too much cold weather, the mixture in the cylinder can become butane-rich because only the propane is vaporising.

Needless to say, propane is the preferred choice for cold weather climates.

This is not an issue in Australia, as propane only is supplied.

Safety Warning About Using 9kg Gas Bottle Instead of a 45kg Gas Bottle

We do not recommend connecting an 9kg gas bottle instead of a 45kg gas bottle if the installation was designed for a 45kg gas bottle.

We do not recommend connecting an 9kg gas bottle instead of a 45kg gas bottle if the installation was designed for a 45kg gas bottle.

Several safety issues can affect your safety and the proper operation of your gas appliance when using the wrong size and capacity.

Safety Issues When Using a 9kg in Lieu of a 45kg Gas Bottle

Using an 9kg gas bottle in lieu of a 45kg gas bottle can cause the following safety hazards:

- The 9kg gas bottle may hang from the pigtail connector to the changeover valve or regulator, as large-capacity gas bottles will have elevated connections suited for taller gas bottles. They should NEVER hand by the pigtail.

- Keeping the 9kg gas bottle level and upright may be difficult as the pigtail does not reach the ground.

- The 9kg gas bottle may not be firmly grounded, creating an ignition and fire hazard. Sitting it on a milk crate is an example of non-grounded support.

In a nutshell, LPG gas cylinders must remain in a stable position when in use or there is a risk they could fall, leak, or cause damage.

Vaporisation Problems – Not Enough Gas

In addition to the safety issues, an 9kg gas bottle only vaporises at a rate of about 19MJ/hr when 80% full at an ambient temperature of 20°C.

In winter, at 0°C, the rate would drop to around 12MJ/hr.

Then, as the contents are used and you get down to 40% remaining, the vaporisation output would be about 6MJ/hr.

As the level gets even lower, the output will continue to drop.

Now compare this to the consumption of common gas appliances:

- 26L continuous flow hot water = 199MJ/hr

- Most common size indoor gas heaters = 25MJ/hr

- Typical cooktop burners = 6 to 13MJ/hr (each)

By using an 9kg LPG bottle for high-capacity burners and heaters (except for small cooktop burners), you are starving the gas appliance for fuel.

That means they may not function properly or they could simply stop working.

Final Thoughts

The right LPG size bottle is necessary to provide sufficient vaporisation rates and stay safe.

This is especially true if you have multiple appliances with a high MJ/hr or BTU/hr rating.

It is also critical in colder weather or if you are supplied with butane LPG.

In this case, ask your LPG provider if your gas appliance can use propane LPG.

Using undersized LPG bottles can cause significant problems.

You’re starving your gas appliance with less fuel, exposing your family and property to a fire hazard caused by a hanging or unstable LPG connection.

The best advice is to go with the original recommendation of your gas fitter.

New Residential LPG customer?

New Business LPG customer?

Existing ELGAS customer?

- Elgas to the Rescue with Helicopter LPG Delivery - November 14, 2024

- Gas Patio Heater Guide: Outdoor Gas Heaters – Outdoor Mushroom Heater - September 22, 2024

- LPG Meaning – LPG Means: What Does LPG Stand For - August 31, 2024

Steve Reynolds

Technical Consultant

Steve Reynolds is a leading expert in the LPG industry with over 22 years of experience. As part of the national management team at ELGAS, Steve ensures the safe and efficient storage, handling, and transportation of LPG. He serves as the lead investigator for incidents and collaborates with authorities on industry developments.

Steve is a technical advisor to Standards Australia and Gas Energy Australia (GEA), and an active member of the World LPG Association (WLPGA), contributing to global standards and technical reviews. He holds a BSc. (Hons) in Industrial Chemistry from UNSW and has held senior safety and technical roles at ELGAS, making him a trusted authority in LPG safety and standards.