Fill Gas Bottle – Refill Gas Bottles at LPG Gas Filling Station

Refill gas bottles is done in two ways: you can fill gas bottle by weight using digital scales or refill gas bottles by decant refilling, using the bleed screw.

To fill gas bottle or bulk LPG tank, it can also be done by a metered tanker.

We’ll look at the details of how to when you refill gas bottles and the pros & cons of both methods of how to fill gas bottle …

Refill Gas Bottles at LPG Fill Station – LPG Filling

You refill gas bottles through the main valve.

As previously mentioned, LPG filling can be done in two ways – fill gas bottle by weight or refill gas bottles by decanting.

As previously mentioned, LPG filling can be done in two ways – fill gas bottle by weight or refill gas bottles by decanting.

LPG filling or refill gas bottles by weight involves inputting the tare weight (empty weight) and the desired amount of gas to fill gas bottle into a digital scale.

The other method to refill gas bottles is referred to as ‘decanting’, which is how to fill gas bottle at servo or refilling at an LPG fill station.

When you refill gas bottles by weight, the LPG filling hose is controlled by the scale, which shuts it off when the appropriate weight is achieved.

To refill gas bottles by decanting, a small vent screw is opened which allows gas to vent when the gas in the bottle reaches the full refilling level.

The venting gas is the refilling operator’s cue to stop the LPG filling and close both the vent screw and main valve, when they fill gas bottle.

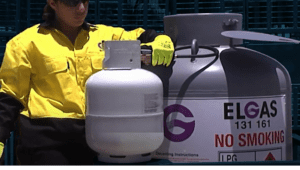

How to Fill Gas Bottle at Servo – LPG Gas Filling Station – Video

Disclaimer: This video on How to Fill Gas Bottle is only a supplement and refresher for those who have completed the Elgas decant LPG filling training course. It is not the complete training course and other training materials apply. Refill gas bottles by decanting must not be attempted by untrained individuals.

Current Inspection Date Required to Fill Gas Bottle or LPG Filling

No matter which of the refill gas bottles or LPG filling methods are used to fill up gas bottle, LPG filling must be done with a current inspection date.

It is the responsibility of the LPG filling technician at the LPG fill station to check the inspection date stamped into the neck ring of the gas bottle before they refill gas bottles.

An LPG gas filling station cannot refill gas bottles when out-of-date until they are re-inspected and stamped with a new inspection date.

Fill Gas Bottle Using Digital Scales

Using digital scales helps ensure proper and safe LPG filling, based on weight.

Using digital scales helps ensure proper and safe LPG filling, based on weight.

When the total weight equals the empty weight plus the appropriate refill gas bottles weight, you can completely fill gas bottle.

The scales are set for each individual LPG filling, based on its empty (tare) weight, as well as the desired weight to fill gas bottle. (see image)

How the Scales Work for LPG Filling

The tare weight (empty weight) is stamped into the neck ring by the bottle manufacturer.

The operator inputs the tare weight of the gas bottle into the scale’s keypad.

After inputting the weight to fill gas bottle, the technician connects it to the LPG supply.

The LPG filling or refill gas bottles is automatically stopped by the digital scale, after reaching the target weight.

This ensures very accurate refill gas bottles and avoids dangerous overfilling or lost value through under filling.

The fill gas bottle accuracy achieved is why the use of digital scales is the preferred method to refill gas bottles.

Not surprisingly, this is how major suppliers, like SWAP’n’GO®, refill gas bottles (fill gas bottle).

Faster Way to Fill Gas Bottle with Carousels at LPG Fill Station

A side benefit of using scales, at an LPG fill station, to fill gas bottle is speed.

The LPG filling line can be pump driven for faster refill gas bottles.

This is not possible with decanting at an LPG gas filling station, as the operator might be too slow to stop the refill gas bottles process.

This could result in dangerous overfilling.

Digital scales and pump driven LPG filling also allow for the use of high speed carousels to fill gas bottle, like the SWAP’n’GO carousel in the accompanying image.

In fully automated LPG fill station plants, with LPG filling carousels, even the keypad step can be automated (see image above).

The carousel digitally reads an RFID chip on the cylinder that contains the tare weight, as well as the rest of the manufacturing specifications to refill gas bottles.

LPG Decanting Procedure to Fill Gas Bottle at Servo – LPG Gas Filling Station

Decanting is the process seen if you have ever watched them fill gas bottle at servo or LPG gas filling station.

To transfer LPG gas from one cylinder to another, you use the decanting method.

After connecting the gas bottle to a larger LPG storage tank, the trained operator begins to LPG filling process until some gas starts leaking out of the loosened bleed screw.

After connecting the gas bottle to a larger LPG storage tank, the trained operator begins to LPG filling process until some gas starts leaking out of the loosened bleed screw.

The LPG filling operator at the LPG gas filling station is supposed to stop refill gas bottles as soon as liquid LPG starts coming out of the bleeder opening.

The liquid LPG escaping is unmistakable, as it looks like a white cloud.

This intentional venting of gas into the atmosphere, when you fill gas bottle, is avoided with the digital scale method.

Decanting can also result in either overfilling or underfilling the gas cylinder, as well as correct gas cylinder fill, depending on the gas bottle and the operator filling it.

For example, if the operator is slow to stop the process when the liquid LPG starts to bleed out, the gas bottle could easily become overfilled.

As previously mentioned, overfilling a gas bottle is a significant safety hazard.

Fill Gas Bottle at Servo – LPG Filling 9kg Gas Bottles

When you fill gas bottle at servo or LPG fill station, it is done using the decanting method.

This is what you see during LPG filling 9kg gas bottles.

After connecting the gas bottle to a larger LPG storage tank, the trained operator begins to fill gas bottle.

They continue to fill gas bottle until some gas starts leaking out of the loosened bleed screw.

Dip Tube Variation Effect on Refill Gas Bottles

In addition to operator performance variances in LPG filling, there are inconsistencies in the dip tube lengths.

Dip tubes can fall out and be missing. The accompanying picture shows some examples.

Dip tubes can fall out and be missing. The accompanying picture shows some examples.

Dip tubes lengths are important because they are connected to the bleed screws.

The refill gas bottles by decanting operator opens the bleed screw to fill gas bottle until the level of LPG filling reaches the bottom of the dip tube, at which point liquid LPG will start to bleed out during refill gas bottles.

This is his signal that the cylinder is full and the LPG filling is complete.

Long dip tubes can result in under refill.

Short or missing dip tubes will cause overfill of the gas cylinder.

A missing dip tube is the worst case scenario because the entire ullage space would be filled, allowing no room for expansion.

This is one of the reasons that swap is a much safer alternative, as dip tube variances have no effect when you fill gas bottle by weight.

20% Oversized for Expansion When You Fill Gas Bottle

LPG vapour pressure rises with temperature.

LPG vapour pressure rises with temperature.

If a gas bottle is exposed to higher temperatures the gas expands, increasing the pressure.

LPG bottles are designed to be full while allowing 20% of the space, called “ullage”, for the natural expansion of the LPG, as shown in the accompanying picture.

Properly refill gas bottles, with the required 20% ullage, should never have a problem.

Overfilling is Unsafe When LPG Filling 9kg Gas Bottles

One of the big advantages of LPG filling 9kg gas bottles, or any size bottle, by weight is the avoidance of dangerous overfilling.

When over filled, a gas bottle has less than 20% ullage, creating the possibility of the unwanted release of gas to the atmosphere, through the pressure relief valve.

The pressure relief valve is incorporated into the main gas valve on the bottle.

It’s actually a valve within a valve that prevents dangerous overpressure situations.

So, overfilling combined with heat can result in gas venting from the pressure relief valve, which creates a significant safety hazard.

This is especially true in the warm Australian climate.

Refill Gas Bottles is NOT a DIY Procedure

To refill gas bottles is not a do-it-yourself handyman procedure and should never be attempted by untrained personnel.

Only trained LPG filling technicians should attempt to fill gas bottle by either method.

Only trained LPG filling technicians should attempt to fill gas bottle by either method.

The trained operators know all about the appropriate procedures.

This includes personal protective equipment (PPE) to wear, static -free clothing, proper cylinder grounding, static electricity hazards, ignition sources, fire protection and more.

In-depth safety training is mandatory for the LPG filling technician at an LPG gas filling station..

Doing it incorrectly could result in cold burns (liquid LPG is -42°C), fire or even an explosion.

In addition dangerous overfilling can occur.

The simple message for people who are thinking about trying LPG filling their own refill gas bottles…

Just DON’T do it!

- Elgas to the Rescue with Helicopter LPG Delivery - November 14, 2024

- Gas Patio Heater Guide: Outdoor Gas Heaters – Outdoor Mushroom Heater - September 22, 2024

- LPG Meaning – LPG Means: What Does LPG Stand For - August 31, 2024